Features

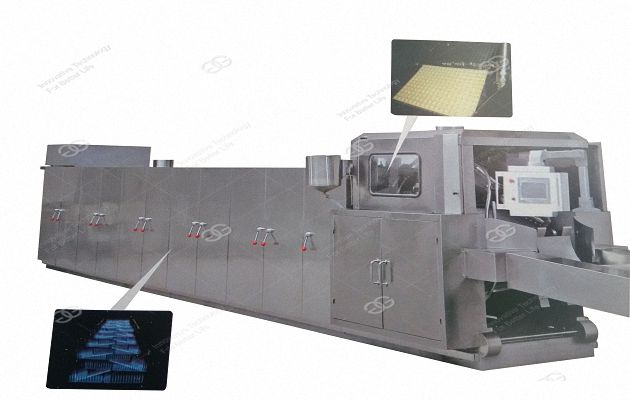

Applicable:Cream spreading machine used to spreading ice cream to wafer biscuit, cake and other snacks.

Features:Automatic spreading, high efficiency, high quality, easy operation and to maintain.

Introduction:Cream spreading machine is an important machine in the wafer line that determines the number of wafer sheets and cream layers required by the manufacturer. This machine has the following functions: to spread cream layer onto the pre-cooled wafer sheets evenly, to make the book of wafers sheets with different layers of cream and sheets, and then press the wafer sheets and cream layers together slightly. The numbers of cream layers and wafer layers can be adjusted as required as 2/3/4,3/4/5,5/6/7. The machine will count them automatically according to the adjustment. There is one device to control temperature automatically and constantly on the roller of filler. The layer thickness can be adjustable, too.

Main parts:

The rack is the structure of 180# galvanized channel steel with SUS201 stainless steel cover.

The creaming head is composite construction, easy to disassemble and assemble, and clean.

The stacking device is circling type.

The pressing device is double-rolling type.

The pressing is made by cylinder, which rise and fall the spreading belt.

The spreading belt is from 5mm rubber light-weight conveying belt.

The electric cabinet is separated from the machine and controlled by PLC on touching screen.

There is no hot wind device.

There is one function to block and discharge when the machine stops.

The whole machine is controlled by PLC and the touching screen can show and adjust the parameter.

The motor is SEW of German brand.

The holder bearing is Chinese famous brand-TR.

The pneumatic components are FESTO or SMC.

The AC contactors are Schneider.

The PLC is Siemens S7-200 or Mitsubishi FX-1N.

The inverter is Danfoss or Panasonic.

The touching screen is Smark line 700 or Hakko.

The photocell is Sick of Cylinder-shaped.

Approach switch: Optex SD-105.

Advantages:

1.Number of cream layers and wafer layers can be adjusted by PLC.

2. Its voltage can be customized both380V and 220V if it is necessary.

3.The machine frame is made of steel with international standard and the cover adopts imported 304 stainless steel plate with thickness of 1.2mm, have a long service life.

4. Adopting hearing medium conduction technology with heating oil as medium,the machine is a new generation product developed exclusively in China based on the advanced structure of existing plants from domestic market and abroad.

5. This machine can spreading wafer biscuit effectively with low defective goods rate.

6. Cream spreading machine equipped with stainless steel shield, using safe power control, safe and reliable operation.