This

wafer biscuit production line produced by wafer biscuits machine manufacturer has 27 mould, with mature design, fully automatic, stable technical performance and quality, baked wafer has uniform surface colour and lustre, and machinery with smooth operation, no abnormal noise.

This production line has high output, low energy consumption, convenient maintenance, simple operation, no pollution, etc. Various electrical and mechanical parts all use well-known brands at home and abroad, long service life. Contact food part adopts 304 stainless steel, food grade PU belt, conform to the health and safety standards.

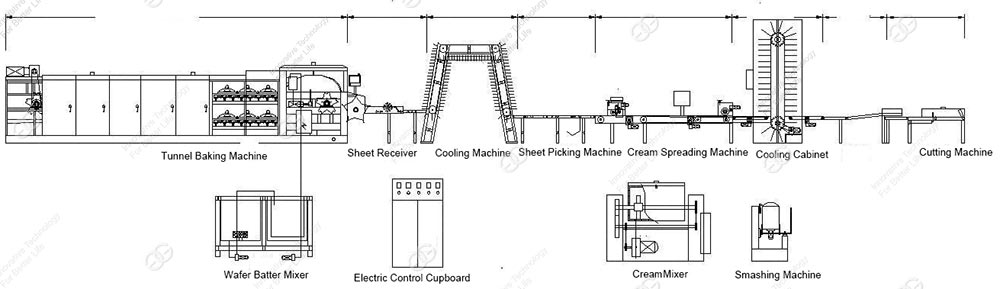

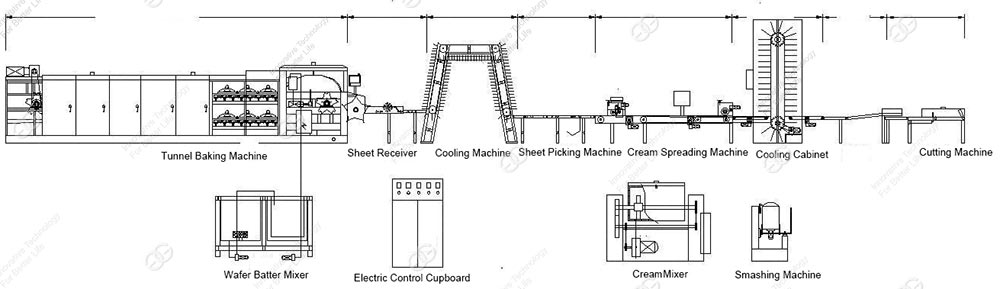

1. Wafer Biscuit Production Process

The whole line including tunnel baking ovens, splicing machine, cooling machine, cream coating machine, and cutting machine, conveyor, control system adopts PLC control, human-machine interface simple operation, easy cleaning and maintenance.

2. Function and Characteristics of Wafer Biscuit Machine

2. Function and Characteristics of Wafer Biscuit Machine

(1). This wafer biscuit line has reliable performance, stable operation, long service life, all electrical equipment, PLC control, bearing all use well-known brands at home and abroad;

(2). High automation, independent operation equipment, and simple operation, convenient maintenance; Rational layout, compact structure, covers an samll area;

(3). Release rate is higher than (equal to) 98%; Unique energy-saving design, low energy, can greatly reduce environmental pollution;

(4). Production line selection under the food hygienic requirements and meet the national standards, the whole machine sheet metal and food contact part adopt 304 stainless steel;

(5). According to the customer demand can customize special production wafer shape, such as large squares, double rolls and animal shape, etc.

Baking oven uses good metal insulation structure, with beautiful appearance, equipped with grouting system, gas heating system, gas leakage alarm system, template transmission and connection device. Burner with high energy-saving combustion technology, greatly improve the utilization rate of combustion. Double baking room insulation structure, make furnace temperature uniformity.

A. Baking oven adopts double furnace chamber structure. Make internal furnace chamber heating effect better, outside the furnace chamber of mechanical part longer service life.

B. The control part adopts Siemens mitsubishi or color touch screen, can display and set the biscuit sheet of running speed, the temperature of baking sheet, the mechanical part, etc.

C. Fuel gas system components adopt brand products at home and abroad, the whole wafer biscuit line bearings adopts import high temperature bearings.

D. The baking plate adopts the grey cast iron. Long service life, the best effect of heat energy, wafer cake uniform coloring, built-in biscuit waste cleaning device.