Features

Full-automatic

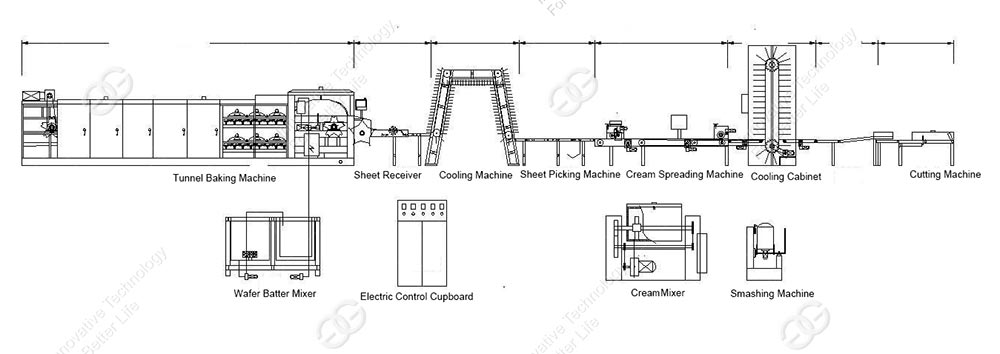

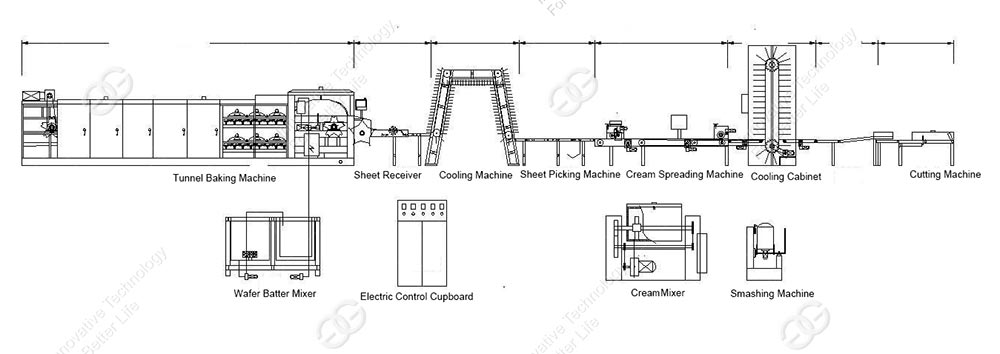

wafer biscuit product line is a new generation of products on the basis of advanced structure of similar products at home and abroad, using electric heating and gas heating for heat source, domestic exclusive development, it has successfully solved the wafer production high cost, the big difference of surface color of biscuit. This production line consists of material mixing system, automatic feeding, tunnel oven, feeding machine, cooling machine, coating machine, slicing machine, etc, with compact structure, good stability, has become the preferred equipment for biscuit industry.

Production line with two kinds of models, one is GAS Heating and the other is Electric Heating ,which has the main function as follows: energy saving, high production capacity, high automation, high recycle, having long working life, convenient operation, few operators, up to the national standard of energy saving and no pollution.

Main Technical and Requirements:

1. The whole shell of the production line adopts 304 Stainless Steel in accordance with the health and safety standard.

2. The electricity and transmission components are all used Siemens, Mitsubishi, touch screen to control and adopts the International Brand Germany SEW, SKF to make the whole line steadily.

3. In according to the clients ' requirements, we can make a wide range of size and shape cream (chocolate ) filled wafer biscuit full automatically.